Maszyna sztancującaBobst

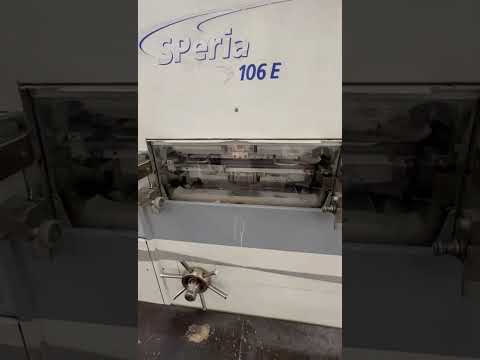

Autoplatine Speria 106 E

Maszyna sztancująca

Bobst

Autoplatine Speria 106 E

Rok produkcji

2006

stan

używany

Lokalizacja

Hlavní město Praha

Pokaż zdjęcia

Pokaż mapę

Dane dotyczące maszyny

- Opis/nazwa maszyny:

- Maszyna sztancująca

- Producent:

- Bobst

- Model:

- Autoplatine Speria 106 E

- Rok produkcji:

- 2006

- stan:

- bardzo dobry (używany)

Cena i lokalizacja

- Lokalizacja:

- Jezkova 1054/10, 13000 Praha 3, Česká republika

Zadzwoń

Szczegóły oferty

- Identyfikator ogłoszenia:

- A202-48585

- Aktualizacja:

- ostatnio dnia 08.12.2025

Opis

Bobst Autoplatine Speria 106 E

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic device for sheet travel control.

- Adjustable centering at stripping station.

- Control cabinet cooling unit.

- Bobst-Electronic machine operating system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor based Bobst system allows the operator to easily control, visualize and check the various functions and elements of the machine.

- Main motor with frequency converter control.

FEEDER

- Pile tray with handle allowing manual lateral correction of the pile during production.

- Synchronization device timing the sheet arrival against the front lays when the machine is at a standstill.

- Pile lifting controlled by Pressfoot.

- Rear pile guides (OS and OOS).

- Side blowers adjustable with Centerline marks.

- Suction unit.

FEED TABLE

Csdpfx Ajxl Talohzepw

- Covered with an anti-static stainless steel plate.

- Feed table inlet equipped with lateral ramps.

4 Front lays, adjustable in pairs with front register control.

- "Pull" guide (OS) adjustable according to Centerline marks, with side register control.

- Double sheet detector.

- Support plates at entry of platen station.

- Sheet hold-down device (guiding the sheets to the front lays).

- Upper frame with manual lifting device.

- Upper transport equipment for paper, paperboard and corrugated board.

- Transport belts.

With lateral guidance and automatic tension system.

PLATEN

- Gripper reopening device.

- Equipment centering and locking.

- Locking of the chase against the upper beam.

- Measurement of the cutting force with strain gauge.

1 Synthetic material supporting plate.

1 Upper chase : fixed bottom plate

1 Cutting plate

WASTE STRIPPING STATION

- Air-cylinder-driven lifting of the upper frame.

1 Upper pull-out frame

Including crossbars and clamps.

1 Lower pull-out frame

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline marks.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Elevated machine l

C Feeder

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Adjustable supporting plate centerings (micro adjustment)

F WASTE STRIPPING STATION

1 F-31 Upper pull-out frame quick-locking device

STANDARD EQUIPMENT

MACHINE

- Centerline system for quick job changeover.

- Electronic device for sheet travel control.

- Adjustable centering at stripping station.

- Control cabinet cooling unit.

- Bobst-Electronic machine operating system C.U.B.E. (Control Unit Bobst Electronic).

This microprocessor based Bobst system allows the operator to easily control, visualize and check the various functions and elements of the machine.

- Main motor with frequency converter control.

FEEDER

- Pile tray with handle allowing manual lateral correction of the pile during production.

- Synchronization device timing the sheet arrival against the front lays when the machine is at a standstill.

- Pile lifting controlled by Pressfoot.

- Rear pile guides (OS and OOS).

- Side blowers adjustable with Centerline marks.

- Suction unit.

FEED TABLE

Csdpfx Ajxl Talohzepw

- Covered with an anti-static stainless steel plate.

- Feed table inlet equipped with lateral ramps.

4 Front lays, adjustable in pairs with front register control.

- "Pull" guide (OS) adjustable according to Centerline marks, with side register control.

- Double sheet detector.

- Support plates at entry of platen station.

- Sheet hold-down device (guiding the sheets to the front lays).

- Upper frame with manual lifting device.

- Upper transport equipment for paper, paperboard and corrugated board.

- Transport belts.

With lateral guidance and automatic tension system.

PLATEN

- Gripper reopening device.

- Equipment centering and locking.

- Locking of the chase against the upper beam.

- Measurement of the cutting force with strain gauge.

1 Synthetic material supporting plate.

1 Upper chase : fixed bottom plate

1 Cutting plate

WASTE STRIPPING STATION

- Air-cylinder-driven lifting of the upper frame.

1 Upper pull-out frame

Including crossbars and clamps.

1 Lower pull-out frame

DELIVERY

- Pile tray.

- Front jogger.

- Adjustable rear and side joggers with Centerline marks.

- Braking brush.

- Manual non-stop rack.

AVAILABLE EXTRAS

B MACHINE

1 B-1 Elevated machine l

C Feeder

1 C-4 Manual non-stop device

E PLATEN

1 E-5 Compensating plate

1 E-55 Adjustable supporting plate centerings (micro adjustment)

F WASTE STRIPPING STATION

1 F-31 Upper pull-out frame quick-locking device

Dostawca

Wskazówka: Zarejestruj się bezpłatnie lub zaloguj, aby uzyskać dostęp do wszystkich informacji.

Wyślij zapytanie

telefon & Fax

+420 229 ... ogłoszenia

Te ogłoszenia mogą Cię również zainteresować.

Ogłoszenia

Legnago

Legnago

947 km

Płyta do sztancowania

ErbaTitan 1 PN

ErbaTitan 1 PN

Ogłoszenia

San Marino

San Marino

1 017 km

Automat do sztancowania

KAMATS 96-1

KAMATS 96-1

Ogłoszenia

Senieji Trakai

Senieji Trakai

491 km

Maszyna do laminowania

Lamina System Fully automatic laminator1620BL

Lamina System Fully automatic laminator1620BL

Ogłoszenia

Alsfeld

Alsfeld

700 km

Tygiel do wybijania

KERMATS 3/E

KERMATS 3/E

Ogłoszenia

Marano Vicentino

Marano Vicentino

894 km

Wyrzynarka precyzyjna

MARIOTTINI1600

MARIOTTINI1600

Ogłoszenia

Henstedt-Ulzburg

Henstedt-Ulzburg

649 km

Składarko-sklejarka

BobstMEDIA-100-II

BobstMEDIA-100-II

Ogłoszenia

Schijndel

Schijndel

941 km

Iberica JRK-105 (2002)

IbericaJRK-105

IbericaJRK-105

Ogłoszenia

Valea Mare-Podgoria

Valea Mare-Podgoria

892 km

Prasa sztancująca

YawaTD 1060S

YawaTD 1060S

Ogłoszenia

Obererbach (Westerwald)

Obererbach (Westerwald)

809 km

KERMA TS-II, 1968 sztanca, podawanie ręczne

WupaKerma TS-II

WupaKerma TS-II

Ogłoszenia

Achern

Achern

869 km

Silnik elektryczny

EKEFlachmotor

EKEFlachmotor

Twoje ogłoszenie zostało pomyślnie usunięte

Wystąpił błąd